Design is one of most important parts of a success mold making project.

Design is one of most important parts of a success mold making project.

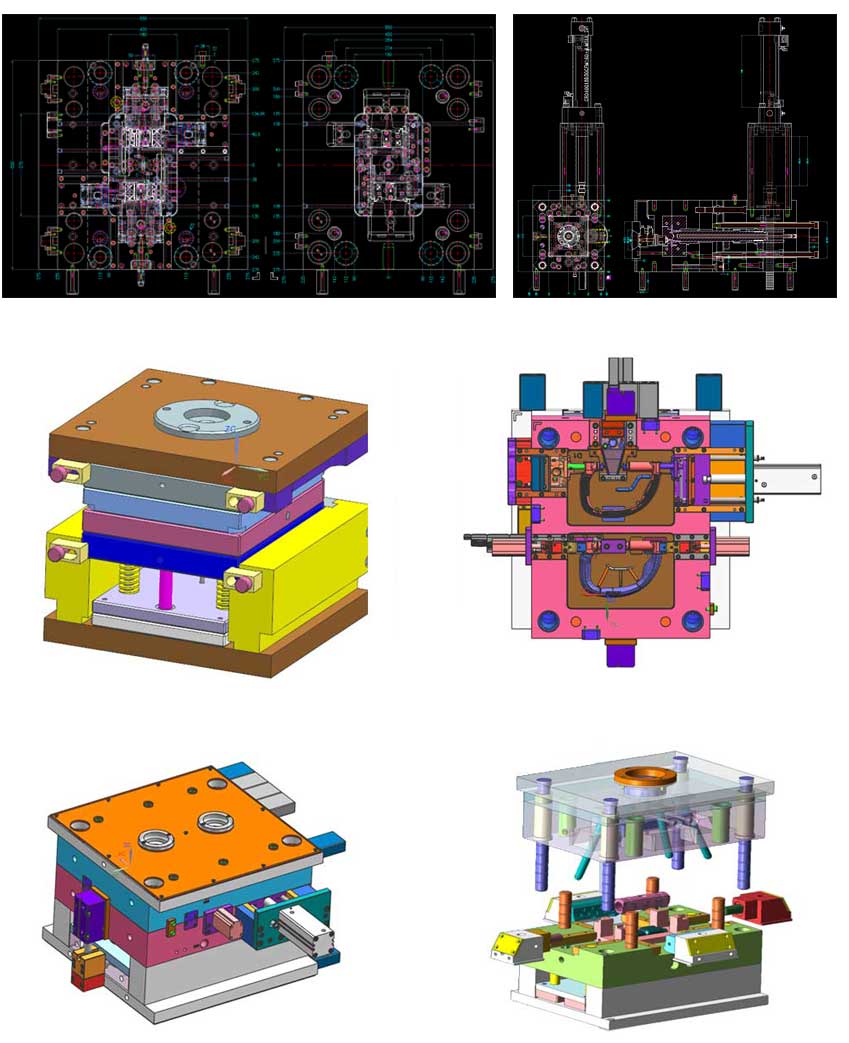

Our teams has years of rich experience in the latest engineering software to directly take the clients’ PART 3D model into mould design. All mould designs are then validated to our clients tooling standards and moulding specifications.

For each new project, we will begin an internal kick-out meeting to decide the part layout like the gate position, Parting line, mould structure, ejection method and cooling layout, etc. These would allow us to provide the best solution to get the mould exactly what you want. Having decades of injection mold design experience makes us to incorporate the “mold ability” factor into our product designs and evaluations.

Our engineering and mould-making technology includes:

1.DFM report

2.AutoCAD (2D )

3.UG (3D)

4.Moldflow analysis

5. Quotations Provided with Preliminary Mould Design / Layout Drawings